This post covers parts prep and assembly of the Hy-Con Gamma Major cage. With the flash hider added, this becomes the externally complete barrel assembly of the T19.101.

Tools:

- Hand Drill Motor

- 5/64" or 2mm drill

- 7/64" drill

- Nearest drill to 3.0mm that you have

- 1/8" drill

- 9/64" drill

- Tap Handle

- 6-32 tap

- 10-24 tap

- Allen wrenches

- Razor blade or sharp pocketknife

- File

Parts/Materials:

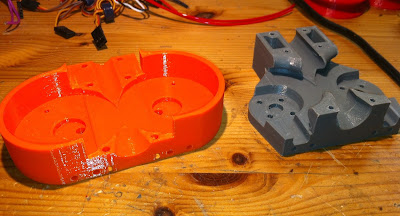

- Hy-Con Gamma Major/Main

- Hy-Con Gamma Major/Cover

- Hy-Con Gen3 Flywheel x 2

- T19 Flash Hider

- Turnigy Multistar V-Spec 2205 2350kv x 2

- M2 6mm length socket or button head cap screw x 8

- M3 10mm length socket or button head cap screw x 8

- 6-32 1" length socket head cap screw x 6

- 6-32 1/2" length socket head cap screw x 3

Start with the cage main section:

Use a 3mm drill (7/64" works for me, as my drill measures 2.98mm) to clean out the 8 motor mount holes. These bolts are locational and should be a close (slips in without play) fit on a M3 fastener. Do not oversize to typical "clearance" fit.

Use a 7/64" drill to clean out the 6 cover-to-main bolt holes (near the bore). This is a tap drill for 6-32 threads. I use this size because it works well for PETG. Other materials may call for changing the tap drill size.

Use a 9/64" drill to clean out the six corresponding 6-32 through holes in the cover. Again, these bolts are semi-locational and should be a close fit.

Use a file to clean any burrs or raised extrusions off the sides of the Main part where it fits into the Cover's guards.

File the top surface of the Main (where the bolt holes are) and the matching surface of the Cover, if necessary. Burrs and debris from the top layer extrusion can prevent proper alignment when torqued down.

File the guard edges on the Cover where they contact the Main surfaces if necessary to relieve any interference and allow assembly.

Use a 7/64 drill to clean out:

- The three flash hider bolt holes (above)

- The four outer mounting holes on the breech flange (below)

N.b.: The inner set of breech flange holes on the Gamma Major are not used in the modern T19. That is an obsolete pattern for compatibility.

Don't drill the holes any deeper than the existing printed pilot bore.

Tap all these 6-32 threads:

- The 6 main-to-cover holes in the Main.

- The 2 flash hider holes and 2 outer mounting holes in the Main.

- The 1 flash hider hole and 2 outer mounting holes in the Cover.

Use a sharp tap and go slow!

Seat the cover and main together and start at least 2 cover bolts for the next step.

Use a blade to clean up the barrel crown and slightly break the edge as a chamfer. The printer can leave a motion system acceleration defect (corner swell) on the crown. This can protrude slightly into the bore and potentially impact accuracy.

Alternatively, one may torque the main and cover parts securely together, then use a countersink cutter to cut the barrel crown.

Next comes flywheels.

Use a 5/64" drill to clean out the 4 flywheel bolt holes.

Use a 1/8" drill to clean out the "3mm" motor shaft clearance hole. (N.b.: This is NOT a pilot bore. I'm telling you to make sure it is oversize for a reason. The Gen3 flywheel is piloted on the rotor outside diameter. This shaft hole SHOULD NOT be a tight fit on the shaft with the Gen3 wheel because it is an overconstraint. If this hole and the rotor bore do not agree perfectly, it can cause the flywheel to be forced to warp when torqued down and thus have runout which is bad.)

Use a blade to scrape down any Z scar/layer change blips and other protruding detritus inside the rotor bore. Careful not to egg it out. Follow the existing surface. Sand slightly, if necessary.

Now comes the time to mate the wheel to the motor. It should be a snug fit with some interference, but should push on easily by hand. Some hand fitting of the bore may be required - take your time, be careful, get the fit right.

Caution: Do not thrust load the motor bearings while fitting the wheel. Support the rear end of the shaft on a surface while pressing on the wheel. DO NOT push on the stator base while fitting the wheel! DO NOT hold the motor in your hand and mash it into the wheel. Place the SHAFT END against a hard surface and push the wheel down onto the rotor. Thrust loading the bearings can brinell them.

Start by visually clocking the rotor and wheel bolt holes to match before putting the wheel onto the rotor. Use an allen key or other tool through one hole to help align the bolt holes while pressing.

Be sure the wheel is fully seated on the rotor (<1mm of the rotor backiron should be visible above the wheel bore edge).

Install 4 M2, 6mm length bolts and torque evenly in a cross pattern.

Repeat for the other rotating assembly.

Mate these to the cage main.

Hint: Insert the phase wires into the phase wire channels first, then jockey the rims past the groove fillers and the rear shaft end/snap ring into the shaft end clearance pocket.

Install 4 M3, 10mm length bolts per motor and torque evenly in a cross pattern.

Now is the time to roll the wheels over by hand and check for excessive runout, contact or other problems. Many wheels do wobble slightly, as is unavoidable in FDM parts, but this should be minimal. In some cases, the flywheel bolts may need to be loosened and retorqued, or the motor and wheel pulled and remated. Major runout or contact of the wheel rim with the cage most likely indicates a significant tolerance issue with one or more of the parts or trapped debris in a fit somewhere.

Once satisfied with the wheel install, check the torque on the bolts.

If you have a motor test setup on hand, connect a suitable drive to each motor at this time, power it up, and give each rotating assembly a test spin. The motors should start and run normally. No wheel rim contact with anything should occur at speed. This is a good time to detect typical lemon motors with shorted turns, which generally exhibit a drag torque. If one wheel stops much faster than the other when undriven, that motor is defective.

Mate the Main and Cover. Start six 6-32, 1" length socket head cap screws.

Torque evenly, starting in the center and alternating sides.

Use a 9/64" drill to clean out the 6-32 through holes in the flash hider and bolt it on with three 6-32, 1/2" length socket head cap screws.

This hole prints at a tappable dimension with high thread engagement, due to the characteristics of the larger 10-24 thread and its taps which will cut cleanly in PETG in such a case, and does not need drilling.

Use a tool to measure the depth of the hole.

Transfer this dimension to the tip of your 10-24 tap with tape.

This will help avoid overpenetrating with the sharp tap tip and DENTING THE BORE. Be mindful!

Go slow and back out every few turns to remove chips. Stop at indicated depth.

Now you have set up what may be your first Hy-Con and the most critical and tedious part of the T19 assembly process is behind you! The rest is more fun now that the high-speed spinny bits and internal ballistic headaches are squared away, don't worry.

Next: Part 3 - Breech Assembly

No comments:

Post a Comment