. . . but I am disappointed.

This Zeus suddenly gave up the ghost when I was testing it last weekend, and this was the cause: a poorly-made solder join on the wire leading directly from the batteries to the motors had come loose.

The lemon lotto is beginning to feel a lot more like lemon Russian roulette; loose wires and misaligned parts are starting to feel almost routine. Poor QC is a minor annoyance to people with screwdrivers and soldering irons, but to the average consumer, this would have been a killer problem - especially if this had come loose during a game.

I've heard of other nerfers having similar problems with their Zeuses. This is no good. Somebody needs to fix their shit and fix it yesterday.

Testing has resumed as of last weekend, with no further problems.

HvZ and nerf news, tech, mods, reviews, tests, builds, opinions and observations from the firing line.

Wednesday, September 16, 2015

Sunday, August 30, 2015

Nerf Rival Zeus - Lightning Link, RS390-4735 Swap, Stock Motor Info

Last time I posted about my Zeus, it was still semi-auto. Shortly after, I decided to change that, because I am strongly dissatisfied with the stock trigger's heavy pull and unreliability at higher ROF. IMO, something else needs to be done or developed aside from the standard Zeus if you want to use Rival automatics as a general-purpose (semi-auto or up to 15rps full auto with precise controllability, in my book) primary.

So my Zeus is now converted to uncontrolled feed. While it isn't the most practical with 25+ rps on a 12 round mag and awkward reload, the trigger is nice, and it is awesome.

There are 4 changes to make in order to get this functionality:

* Remove the ram lever and its torsion spring.

* Remove the rear gate and its shaft and torsion spring.

* Grind out the detent on the right feed housing half. Visible at front inside the feed path

* Grind out the detent on the front gate (the thin area above the semicircular curve). You want this gate to match the feed path seamlessly when fully open.

After doing so you will have screaming fast full auto - take a loaded mag, open the detent by hand, see the balls shoot out? That fast, except going downrange at a hundred odd fps. It's a great special weapon. Unfortunately, I can't think up a good selective fire or 2-stage trigger strategy using the stock parts.

EDIT: I guess I forgot to update this, but my advice is to avoid straight motor swaps to anything higher torque than the stock 360 on these flywheels. They will NOT hold up to any more torque with the stock hubs. This setup hammered out one of the shaft bores in the flywheel about a month later. If you want to replace, fix or upgrade motors for these stock flywheels, look into brushless outrunners.

The search for good Zeus motors has been ongoing, and thanks to /u/farmcoffee on Reddit (member of the Draugr team) I received a free pair of this 0.47mm/35 turn 390 motor which was my first stab at it.

Specs on this are sparse as with most Chinese motors, but what is specified is 21000RPM@11.1V giving a kv of 1892 - fairly low for a 35 turn wind, but such is the expectation for a long armature with this sort of aspect ratio like the 390 "stretch" motor. You can also see this with 130 and 180 motors and their turn count versus kv.

I did encounter a snag. I was sent two motors obviously of different batches. One had stronger magnets and different color leads, and definitely revved slower as is expected from the magnets. Not exactly promising for prospective buyers of these for Zeus installs. These motors, however, have external flux rings - a steel sleeve on the outside of the can, to provide an additional magnetic path. These are removable and optional, and removing them is equivalent to weakening the magnets - adding speed, reducing stall torque slightly, and reshaping the torque curve as expected from these changes; so I ended up removing the ring from the slower motor, cutting it in half and putting it back on and bam, perfect speed match. Even with the flywheel load and the imbalance of the stock Zeus flies, they match about as well as any .50 cal gun ever would - Not shabby at all.

This is also the first time I (or anyone?) has pulled the stock motors from a Zeus:

Once again confirming 360. Appears to be a Johnson clone. I don't think Hasbro ever uses genuine motors, it's all Chinese generics except those SMCs in the barricade. Also we have 24000rpm@9.6V printed on the can, and this gives a kv of 2500.

The 3160 wind is rather weird to me because it seems to be deliberately suboptimal copper fill. Note that a common AEG motor (Stampede, Swarmfire, Vulcan) is a Mabuchi clone RS360PH-3560 meaning the standard 300 series armature stack can take at least 0.35mm wire at 60 turns. In any case it is unfortunate that this motor is wound this way, although it works fine it could have had more guts with 0.35mm wire. Was this something to do with current and the C cells perhaps?

The shaft is 2.3mm (of course), 8mm protrusion from the bearing and a total stickout of 11mm from the mounting surface. It has the typical rolled splines for extra grip that a lot of 300 series shafts have. Doesn't seem that critical, the flywheels install super tight. This however is a shorter shaft than I expected. That is good, makes finding suitable motors easier as virtually ALL of the 300 series motors in existence will mount this flywheel properly.

Mod wise on the gun:

* The Zeus has rubber sleeve style mounts. Those familar with Stampede gearboxes will remember them. I had to trim about 1/4" off the top edge of mine to clear the flux rings on the 390s which needed to stay since I matched my motors by modding them.

* The stock hold-down brackets are used with longer screws. Be careful not to overtorque and break/bend the bracket since it doesn't seat against anything now. FYI, mounting the motors with screws into the can is NOT possible with the stock flywheels because the flywheel web runs SUPER close to the mount socket surface. Unless you countersunk the screw perfectly (which might make it weak) you need to clamp your motors into the socket from the outside. Similarly, you need either the stock rubber or a shim between the can and the bottom of the mount socket. The bearing snout hole in the socket will align the motors without the rubber, but the bearing snout will stick out too far into the inside of the cage and hit the flywheel.

* Normal clearance hole in the left shell.

* Shafts zipped to length after installation. Necessary to clear some stuff, BTW.

As an update, here is what I have done endbell cover wise:

And a little fix for the nasty sharp edge underneath as well. No paint yet.

Some other stuff:

* Flywheel installation depth is with the vertex of the V-grooved flywheel surface set just below the edge of the cage.

* You can probably remove these flywheels with a proper puller, but the easiest method for most is to suspend the cage with the motor hanging free and the flywheel sitting against the mount socket, and drive the motor shaft through with a punch smaller than 2.3mm (I used an old 130 armature).

* I found some evidence of contact of the flywheels with the cage: OD of mount socket (due to mold flash inside the fly that I removed) and face of mount socket due to install depth. This was all factory. If something seems to have friction or make a funny noise in a zeus, investigate it, there is very little clearance in these things and rubbing flywheels is a possibility.

* Pinion removal on larger motors (if you receive or scavenge a motor with a pinion on it) - use proper puller or lock pinion in vise and drive shaft through with <2.3mm punch. Don't pry against the can. You can do that with little motor stuff, not these.

As I expected, these motors wanted 4S, so I am using the same 4 cell pack I was thrashing my stock motors on. By the numbers that is 28000RPM unloaded - compare to stock motors on 3S at 27750RPM unloaded (and smaller in comparison to the static load).Chrono data incoming but it shoots nominally.

Chrono session:

115.3

115.2

113.1

118.1

114.0

110.5

119.7

121.1

107.6

119.8

108.1

116.5

113.4

116.3

117.6

Units of feet per second. Mostly dead battery!

Handling of high ROF is definitely improved, I haven't seen a visible shootdown problem yet. It definitely doesn't get droopy and inaccurate on the end of a mag dump like the stocks did.

Response is improved as well.

Speed match is improved substantially.

Stall torque is now sufficient to not be jammable by feeding a ball into stopped flywheels. The 390 motors have enough grunt to force through even the densest Rival ball from a standstill, and if you are familiar with how much crush the Zeus cage has and how damn hard it is to manually push the balls through the flywheels that is seriously impressive. The brushes aren't even broken in yet and the battery is half dead! The stock 360s didn't have a chance of recovering from that.

It is nice to be able to pin numbers on things for sure now that we have stock motor wind and kv data. Aim for 28000+ rpm and as much torque as possible.

I think next I have to explore the RS380SH-4535 and -4045 and similar winds. It is a much more common motor, and genuine Mabuchis are readily available (a good thing, so you don't end up like me hacking around with flux rings or getting lemons of sketchy Chinese motors); and also a bit shorter than the 390, simplifying the mount and cover mods.

In the end though, I think the stock motors are absolutely fine. If you are only shooting semi-auto, there is not one reason to replace them. Just wire properly and run 3S and you are good to go. Couldn't be easier to understand, and it's a nice change from the little fiddly 130s and shitty metal brushes that you have to confront in a stock .50 cal flywheeler.

So my Zeus is now converted to uncontrolled feed. While it isn't the most practical with 25+ rps on a 12 round mag and awkward reload, the trigger is nice, and it is awesome.

There are 4 changes to make in order to get this functionality:

* Remove the ram lever and its torsion spring.

* Remove the rear gate and its shaft and torsion spring.

* Grind out the detent on the right feed housing half. Visible at front inside the feed path

* Grind out the detent on the front gate (the thin area above the semicircular curve). You want this gate to match the feed path seamlessly when fully open.

After doing so you will have screaming fast full auto - take a loaded mag, open the detent by hand, see the balls shoot out? That fast, except going downrange at a hundred odd fps. It's a great special weapon. Unfortunately, I can't think up a good selective fire or 2-stage trigger strategy using the stock parts.

Motor Upgrades

EDIT: I guess I forgot to update this, but my advice is to avoid straight motor swaps to anything higher torque than the stock 360 on these flywheels. They will NOT hold up to any more torque with the stock hubs. This setup hammered out one of the shaft bores in the flywheel about a month later. If you want to replace, fix or upgrade motors for these stock flywheels, look into brushless outrunners.

The search for good Zeus motors has been ongoing, and thanks to /u/farmcoffee on Reddit (member of the Draugr team) I received a free pair of this 0.47mm/35 turn 390 motor which was my first stab at it.

Specs on this are sparse as with most Chinese motors, but what is specified is 21000RPM@11.1V giving a kv of 1892 - fairly low for a 35 turn wind, but such is the expectation for a long armature with this sort of aspect ratio like the 390 "stretch" motor. You can also see this with 130 and 180 motors and their turn count versus kv.

I did encounter a snag. I was sent two motors obviously of different batches. One had stronger magnets and different color leads, and definitely revved slower as is expected from the magnets. Not exactly promising for prospective buyers of these for Zeus installs. These motors, however, have external flux rings - a steel sleeve on the outside of the can, to provide an additional magnetic path. These are removable and optional, and removing them is equivalent to weakening the magnets - adding speed, reducing stall torque slightly, and reshaping the torque curve as expected from these changes; so I ended up removing the ring from the slower motor, cutting it in half and putting it back on and bam, perfect speed match. Even with the flywheel load and the imbalance of the stock Zeus flies, they match about as well as any .50 cal gun ever would - Not shabby at all.

Stock Motors

This is also the first time I (or anyone?) has pulled the stock motors from a Zeus:

Once again confirming 360. Appears to be a Johnson clone. I don't think Hasbro ever uses genuine motors, it's all Chinese generics except those SMCs in the barricade. Also we have 24000rpm@9.6V printed on the can, and this gives a kv of 2500.

The 3160 wind is rather weird to me because it seems to be deliberately suboptimal copper fill. Note that a common AEG motor (Stampede, Swarmfire, Vulcan) is a Mabuchi clone RS360PH-3560 meaning the standard 300 series armature stack can take at least 0.35mm wire at 60 turns. In any case it is unfortunate that this motor is wound this way, although it works fine it could have had more guts with 0.35mm wire. Was this something to do with current and the C cells perhaps?

The shaft is 2.3mm (of course), 8mm protrusion from the bearing and a total stickout of 11mm from the mounting surface. It has the typical rolled splines for extra grip that a lot of 300 series shafts have. Doesn't seem that critical, the flywheels install super tight. This however is a shorter shaft than I expected. That is good, makes finding suitable motors easier as virtually ALL of the 300 series motors in existence will mount this flywheel properly.

Mod wise on the gun:

* The Zeus has rubber sleeve style mounts. Those familar with Stampede gearboxes will remember them. I had to trim about 1/4" off the top edge of mine to clear the flux rings on the 390s which needed to stay since I matched my motors by modding them.

* The stock hold-down brackets are used with longer screws. Be careful not to overtorque and break/bend the bracket since it doesn't seat against anything now. FYI, mounting the motors with screws into the can is NOT possible with the stock flywheels because the flywheel web runs SUPER close to the mount socket surface. Unless you countersunk the screw perfectly (which might make it weak) you need to clamp your motors into the socket from the outside. Similarly, you need either the stock rubber or a shim between the can and the bottom of the mount socket. The bearing snout hole in the socket will align the motors without the rubber, but the bearing snout will stick out too far into the inside of the cage and hit the flywheel.

* Normal clearance hole in the left shell.

* Shafts zipped to length after installation. Necessary to clear some stuff, BTW.

As an update, here is what I have done endbell cover wise:

And a little fix for the nasty sharp edge underneath as well. No paint yet.

Some other stuff:

* Flywheel installation depth is with the vertex of the V-grooved flywheel surface set just below the edge of the cage.

* You can probably remove these flywheels with a proper puller, but the easiest method for most is to suspend the cage with the motor hanging free and the flywheel sitting against the mount socket, and drive the motor shaft through with a punch smaller than 2.3mm (I used an old 130 armature).

* I found some evidence of contact of the flywheels with the cage: OD of mount socket (due to mold flash inside the fly that I removed) and face of mount socket due to install depth. This was all factory. If something seems to have friction or make a funny noise in a zeus, investigate it, there is very little clearance in these things and rubbing flywheels is a possibility.

* Pinion removal on larger motors (if you receive or scavenge a motor with a pinion on it) - use proper puller or lock pinion in vise and drive shaft through with <2.3mm punch. Don't pry against the can. You can do that with little motor stuff, not these.

Results

As I expected, these motors wanted 4S, so I am using the same 4 cell pack I was thrashing my stock motors on. By the numbers that is 28000RPM unloaded - compare to stock motors on 3S at 27750RPM unloaded (and smaller in comparison to the static load).

Chrono session:

115.3

115.2

113.1

118.1

114.0

110.5

119.7

121.1

107.6

119.8

108.1

116.5

113.4

116.3

117.6

Units of feet per second. Mostly dead battery!

Handling of high ROF is definitely improved, I haven't seen a visible shootdown problem yet. It definitely doesn't get droopy and inaccurate on the end of a mag dump like the stocks did.

Response is improved as well.

Speed match is improved substantially.

Stall torque is now sufficient to not be jammable by feeding a ball into stopped flywheels. The 390 motors have enough grunt to force through even the densest Rival ball from a standstill, and if you are familiar with how much crush the Zeus cage has and how damn hard it is to manually push the balls through the flywheels that is seriously impressive. The brushes aren't even broken in yet and the battery is half dead! The stock 360s didn't have a chance of recovering from that.

It is nice to be able to pin numbers on things for sure now that we have stock motor wind and kv data. Aim for 28000+ rpm and as much torque as possible.

I think next I have to explore the RS380SH-4535 and -4045 and similar winds. It is a much more common motor, and genuine Mabuchis are readily available (a good thing, so you don't end up like me hacking around with flux rings or getting lemons of sketchy Chinese motors); and also a bit shorter than the 390, simplifying the mount and cover mods.

In the end though, I think the stock motors are absolutely fine. If you are only shooting semi-auto, there is not one reason to replace them. Just wire properly and run 3S and you are good to go. Couldn't be easier to understand, and it's a nice change from the little fiddly 130s and shitty metal brushes that you have to confront in a stock .50 cal flywheeler.

Thursday, August 6, 2015

PSA - Do Not Buy - Nichibo FK-180SH-3240 = Scam! Metal Brush Junk!

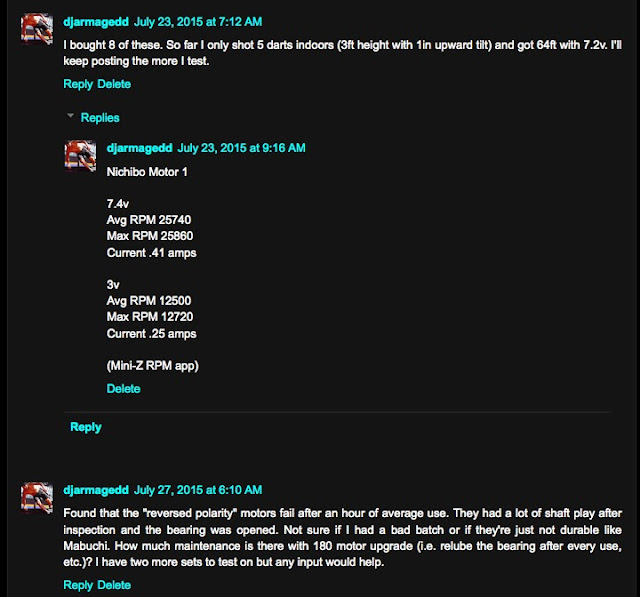

I received a few comments from someone who decided to test out these Nichibo -3240 motors that Zinky86 on ebay was "able to get in" (http://www.ebay.com/itm/121624679840)...

Well, that's conclusive. 2 separate reports. I have not received that set from meishel to test but no need now.

I don't know what it is about the FK180SH-3240 that makes it so attractive for lowballers to slam metal brushes in! Hell, even the China clone variety FK motors have proper carbon brushes, and seriously, if you look at a 3240 armature and think "That will work with metal brushes for more than 5 minutes" you're an idiot, there is NO way that can have a legitimate purpose.

What's more is that the designation "FK" is a LIE. "K" specifies carbon brushes. It's very unambiguous, go look at the Mabuchi website. To put "FK" on a metal brush motor is misrepresenting the product. Same with Kysan Electronics - the Draugr team checked already and until we asked specifically they had the damn thing labeled as an FK with not a peep about metal brushes, and the specs were ripped from Mabuchi's datasheet on the real motor.

This is what Zinky86 had to say about the Nichibo -3240 motor:

This does not reflect positively on Zinky86, nor Nichibo, at all. I am going to give Zinky the benefit of the doubt and assume he was sold this motor believing it to be a clone from a reliable and experienced manufacturer, but I am still disappointed that the problem was not caught until members of our hobby bought fraudulent product.

And Nichibo, what the fuck?

Well, that's conclusive. 2 separate reports. I have not received that set from meishel to test but no need now.

I don't know what it is about the FK180SH-3240 that makes it so attractive for lowballers to slam metal brushes in! Hell, even the China clone variety FK motors have proper carbon brushes, and seriously, if you look at a 3240 armature and think "That will work with metal brushes for more than 5 minutes" you're an idiot, there is NO way that can have a legitimate purpose.

What's more is that the designation "FK" is a LIE. "K" specifies carbon brushes. It's very unambiguous, go look at the Mabuchi website. To put "FK" on a metal brush motor is misrepresenting the product. Same with Kysan Electronics - the Draugr team checked already and until we asked specifically they had the damn thing labeled as an FK with not a peep about metal brushes, and the specs were ripped from Mabuchi's datasheet on the real motor.

This is what Zinky86 had to say about the Nichibo -3240 motor:

This does not reflect positively on Zinky86, nor Nichibo, at all. I am going to give Zinky the benefit of the doubt and assume he was sold this motor believing it to be a clone from a reliable and experienced manufacturer, but I am still disappointed that the problem was not caught until members of our hobby bought fraudulent product.

And Nichibo, what the fuck?

Wednesday, August 5, 2015

Shelf Watch 08-05-15: Gimmick Central, with a side of Rival Ammo

Lakeland TRU: Nerf "Super Soaker" squirt guns. No, seriously. Fancier, beefier dimestore water guns. Zipfire - has this been spotted yet? Does anyone care?

Circa 2010-2013 Nerfsoakers are now getting knocked off. Well doesn't THAT look familiar.

And a Modulus unceremoniously thrown on the floor with a Sonic Fire Strongarm and a NOS pack of XLR ammo. I didn't do it...

Downvote Blast.

Tuesday, August 4, 2015

Saturday, July 25, 2015

Shelf Watch Late July'15 and Superstock Randoms

The reddits have been doing a great job of watching the various stores and vendors lately, so just a few local sightings:

Buzzbee Tyrant at Wal-Mart Lakeland, FL

The larger model of Buzzbee's breakout magfed 20mm products, this thing is huge, and retails for about $20 and comes with a 12 round magazine. You can check out the reviews and internals on reddit.

The lack of a stock and pump grip are inexplicable, and my only real issue with Buzzbee's design decisions. This particular gun is close to being a market segment dominator. If it were to have a stock and a pump grip, it would easily throw all of Nerf's current and likely future (since they closed the door on magfed, idiots they are) Mega offerings into the junk pile of obsolescence.

If you ask me, the smaller version (Boss) should have remained a purpose-made pistol with a top slide, and this, instead of being simply the same functional thing with extra empty space, should have had a stock, and a pump grip.

Oh, if you haven't heard, this gear - mags, guns, ammo - are all compatible with Nerf stuff and other aftermarket products intended to be compatible with Nerf. The industry standards are forged. Bring on the competition.

And now we have Crossbolts at a TRU, same city:

Nuff said, they are out there if you want them.

Now here's the story behind the last post. T3.1 flywheel cage. Nice buildup, and those Rayven flywheels did shoot real nice...

...but the shaft fit troubles continue. You can see that bottom fly has backed off the shaft.

And left a nice witness mark in the cage.

Consider that a failed experiment. Rayven flywheels are NOT suitable for 180 service. The torque is probably to blame, every hard start makes the fly creep a bit on the shaft until it loses too much engagement and the imbalance starts levering it around until it comes off.

I might try coatings on the shafts to tighten the fits. You can't bond to Delrin so anaerobic assembly compounds (Loctite and bearing lockers) are off the board but the shaft could be pre-coated with something to tighten the press fit. CA glue, likely candidate.

Shaft fit problems are one of the biggest headaches with flywheel guns. I have seen what should be solid setups spin flies off with no rhyme or reason. It's half the reason I carry a secondary. I have high hopes for the current T3.1 setup, it is the same as the T2.1 that has been going without any movement of the flies since day one well over a year ago.

While I had it apart, this is the modular cage unplugged. 14AWG Teflon main leads and 16 jumpers, genuine Deans. This is a place where Deans is the only real choice because...

...this is where the connector pair goes when installed. OldNoob, this might give you ideas for how to not have any under-cage space in a build and keep cage modularity. Wire straddles the screw bosses.

Now, after this happened, I quickly snagged some Rapid Reds in trade for stuff, and popped a fly set in. I was planning on going to UGA '15 and I would have run these for that, but people flaked and it didn't happen.

Rapid Red flywheels are decent. Good tight shaft fits, good quality and balance, similar rim thickness and inertia to Stryfe flies. They can work, and work reliably, but I noticed a bothersome issue with them.

They have a real hard time developing the normal buildup layer. This was after cleaning with IPA and then 400+ rounds of breakin! There was a lot of dart material in the receiver and handguards near the cage and not that much on the flywheels.

Cause is definitely the surface finish on these. It is a fine blast or pebble type texture, like you would find on some ABS parts as a finished exterior surface.

Apparently the mirror polish on older type flywheels is critical to the buildup development. A bit counterintuitive but definitely an important bit of flywheel engineering.

Without buildup established more than ~20% on these, they were missing 5-10 fps versus Stryfe/Rayven flies.

Stryfe (shiny) on left, Rapidred (dull) on right. Note it appears they shot blasted the entire mold for these things for reason unknown, and it is clearly a different tool based on the position of gate marks.

I find this quite strange about Hasbro. They will manufacture 2, 5, 10... guns that share functionally identical parts, but it's almost like the designers operate in total isolation. Sometimes there are parts that are functionally identcial, but not mechanically identical and not interchangeable. Other times, as with the whole streamline flywheel lineup, parts will be mechanically more or less identical, and interchangeable, but are different, each designed from scratch and manufactured differently. Such is the case here.

Why do all these guns have their own unique flywheels made on unique tooling? How can this possibly be efficient or cost effective?

In any case Stryfe flies went in and breakin shoot commenced as usual. Buildup is returning and is about 75% and it is back on the ready line. Left the 1600mAh battery in there for now because it's big enough, I will probably put the 2500mAh in something new to test.

The WASP was also fielded a couple days back, along with its Blastersmiths UK Mk4 holster:

This combo did extremely well. Had zero issues with comfort or rotation.

I also switched my dump pouch to its final location, and played my first game ever without sending a single magazine to the deck. Things are finally, 5 years later, starting to fall into place with gear. For the sort of player I am, I never have been on the bleeding edge in that regard.

Buzzbee Tyrant at Wal-Mart Lakeland, FL

The larger model of Buzzbee's breakout magfed 20mm products, this thing is huge, and retails for about $20 and comes with a 12 round magazine. You can check out the reviews and internals on reddit.

The lack of a stock and pump grip are inexplicable, and my only real issue with Buzzbee's design decisions. This particular gun is close to being a market segment dominator. If it were to have a stock and a pump grip, it would easily throw all of Nerf's current and likely future (since they closed the door on magfed, idiots they are) Mega offerings into the junk pile of obsolescence.

If you ask me, the smaller version (Boss) should have remained a purpose-made pistol with a top slide, and this, instead of being simply the same functional thing with extra empty space, should have had a stock, and a pump grip.

Oh, if you haven't heard, this gear - mags, guns, ammo - are all compatible with Nerf stuff and other aftermarket products intended to be compatible with Nerf. The industry standards are forged. Bring on the competition.

And now we have Crossbolts at a TRU, same city:

Nuff said, they are out there if you want them.

Now here's the story behind the last post. T3.1 flywheel cage. Nice buildup, and those Rayven flywheels did shoot real nice...

...but the shaft fit troubles continue. You can see that bottom fly has backed off the shaft.

And left a nice witness mark in the cage.

Consider that a failed experiment. Rayven flywheels are NOT suitable for 180 service. The torque is probably to blame, every hard start makes the fly creep a bit on the shaft until it loses too much engagement and the imbalance starts levering it around until it comes off.

I might try coatings on the shafts to tighten the fits. You can't bond to Delrin so anaerobic assembly compounds (Loctite and bearing lockers) are off the board but the shaft could be pre-coated with something to tighten the press fit. CA glue, likely candidate.

Shaft fit problems are one of the biggest headaches with flywheel guns. I have seen what should be solid setups spin flies off with no rhyme or reason. It's half the reason I carry a secondary. I have high hopes for the current T3.1 setup, it is the same as the T2.1 that has been going without any movement of the flies since day one well over a year ago.

While I had it apart, this is the modular cage unplugged. 14AWG Teflon main leads and 16 jumpers, genuine Deans. This is a place where Deans is the only real choice because...

...this is where the connector pair goes when installed. OldNoob, this might give you ideas for how to not have any under-cage space in a build and keep cage modularity. Wire straddles the screw bosses.

Now, after this happened, I quickly snagged some Rapid Reds in trade for stuff, and popped a fly set in. I was planning on going to UGA '15 and I would have run these for that, but people flaked and it didn't happen.

Rapid Red flywheels are decent. Good tight shaft fits, good quality and balance, similar rim thickness and inertia to Stryfe flies. They can work, and work reliably, but I noticed a bothersome issue with them.

They have a real hard time developing the normal buildup layer. This was after cleaning with IPA and then 400+ rounds of breakin! There was a lot of dart material in the receiver and handguards near the cage and not that much on the flywheels.

Cause is definitely the surface finish on these. It is a fine blast or pebble type texture, like you would find on some ABS parts as a finished exterior surface.

Apparently the mirror polish on older type flywheels is critical to the buildup development. A bit counterintuitive but definitely an important bit of flywheel engineering.

Without buildup established more than ~20% on these, they were missing 5-10 fps versus Stryfe/Rayven flies.

Stryfe (shiny) on left, Rapidred (dull) on right. Note it appears they shot blasted the entire mold for these things for reason unknown, and it is clearly a different tool based on the position of gate marks.

I find this quite strange about Hasbro. They will manufacture 2, 5, 10... guns that share functionally identical parts, but it's almost like the designers operate in total isolation. Sometimes there are parts that are functionally identcial, but not mechanically identical and not interchangeable. Other times, as with the whole streamline flywheel lineup, parts will be mechanically more or less identical, and interchangeable, but are different, each designed from scratch and manufactured differently. Such is the case here.

Why do all these guns have their own unique flywheels made on unique tooling? How can this possibly be efficient or cost effective?

In any case Stryfe flies went in and breakin shoot commenced as usual. Buildup is returning and is about 75% and it is back on the ready line. Left the 1600mAh battery in there for now because it's big enough, I will probably put the 2500mAh in something new to test.

The WASP was also fielded a couple days back, along with its Blastersmiths UK Mk4 holster:

This combo did extremely well. Had zero issues with comfort or rotation.

I also switched my dump pouch to its final location, and played my first game ever without sending a single magazine to the deck. Things are finally, 5 years later, starting to fall into place with gear. For the sort of player I am, I never have been on the bleeding edge in that regard.

Tuesday, July 21, 2015

PSA: Rayven Flywheels = No Go

I just played a game on a backup gun. Hooray for backup guns! Lesson here, don't run Rayven flywheels no matter if the shaft fits seem tight or not! They WILL walk off the shaft sooner or later.

I was also seeing a very noticeable disparity in response between Rayven flywheels and Stryfe flywheels. The latter are lighter. Inertia may seem like your friend, but it is your enemy.

Off to hunt a good balanced set of Stryfe flywheels once again.

The upside is that it gives me an excuse to stick that shiny new 2500mAh battery in there and nix the JST-XH while I am at it.

I was also seeing a very noticeable disparity in response between Rayven flywheels and Stryfe flywheels. The latter are lighter. Inertia may seem like your friend, but it is your enemy.

Off to hunt a good balanced set of Stryfe flywheels once again.

The upside is that it gives me an excuse to stick that shiny new 2500mAh battery in there and nix the JST-XH while I am at it.

Saturday, July 18, 2015

Monolith Developments

If you follow my nerf stuff you will know I build these cylindrical high current lithium-ion packs. Here are the latest experiments.

First of all I am giving this Samsung INR18650-25R cell a shot.

Just a clarification on what I talked about earlier:

The Samsung 20R and 25R are not quite "the same cell with increased capacity". The 25R sags slightly more under heavy continuous loads. The cell that compares on IR and 20-30A performance to the Sonys I have used in the past is the 2000mAh 20R. This one trades off punch for capacity to some extent.

There is a 2500mAh cell that doesn't trade off anything, and that is the Sony VTC5, which is extremely expensive as cells go but is what I would use if someone wanted the best 18650 cylindrical pack available.

I went with the 25 this time because I want to test it. If it can perform great on a RS build and have 2500mAh at this cell cost, it has an application. And it certainly should perform great. This is all hair splitting and this cell still has major guts.

This is what the welded blank looks like for a Tacmod type, 2 cell stick. As usual - double thickness with 8x0.15mm nickel tab stock, split ends, 8 welds per tab end with the redneck 1 farad cap/SCR spot welder.

I want to upgrade that welder with another capacitor so I can increase the electrode tip size and make a bigger weld. However it does fine and I have never had a weld problem or a tab ever come off a cell. I even accidentally shot through 2 layers of tab at once during this build and it welded them to the cell just fine.

This is what it looks like wired. 14AWG discharge leads and 20AWG balance taps, silicone insulated fine strand.

Above pack shrinkwrapped and terminated.

As usual in end-to-end packs there is an insulating mica board piece under that center tab on the positive side.

This is something new I am trying; W.S. Deans micro connectors as balance taps.

Typically I have used industry standard JST-XH connectors for balance taps and I buy prewired pigtails. I have tried as hard as I could to be standard, but I have had too many problems with JST-XH. In my opinion it is just not durable enough to be used repeatedly and constantly for charging.

It is also difficult to terminate in the field. It is a common type of production connector with separate contacts designed to be crimped to the wire and then inserted into the plastic housing. The pigtails (buying and working with) are a bit of a pain and I don't like the quality of the wire I get with them.

In general I don't like connectors in which the pin is removable. I have had these JSTs spit out pins when plugged in. This is obviously bad, as you could have live metal floating around inside a gun.

2 cell packs have 3 wire tap cables. 3 cell packs have 4. 1S packs don't have or need balance taps. Those are the majority of nerf applications and this type connector covers them. The 4 pin Deans micro is usually red and the 3 pin always black, a convenient color code.

At least for internal charge systems, I will be switching my batteries to this style connector.

Size comparison. The Deans 3 pin is actually smaller and more streamlined than the JST.

The mating connector. These are polarized of course. One pin is offset. I wire the offset pin to the positive end of the pack.

Isn't that neat?

Mega and micro comparison to this pack.

That ought to give an idea of where these can be fit. Primarily these sticks are a stock or buffer tube battery.

With a bunch of other assorted packs. Red cells are Sanyo UR18650SAX, green cells are Sony US18650VTC3, black pack is a 4S Sanyo SAX for a Stampede.

First of all I am giving this Samsung INR18650-25R cell a shot.

Just a clarification on what I talked about earlier:

The Samsung 20R and 25R are not quite "the same cell with increased capacity". The 25R sags slightly more under heavy continuous loads. The cell that compares on IR and 20-30A performance to the Sonys I have used in the past is the 2000mAh 20R. This one trades off punch for capacity to some extent.

There is a 2500mAh cell that doesn't trade off anything, and that is the Sony VTC5, which is extremely expensive as cells go but is what I would use if someone wanted the best 18650 cylindrical pack available.

I went with the 25 this time because I want to test it. If it can perform great on a RS build and have 2500mAh at this cell cost, it has an application. And it certainly should perform great. This is all hair splitting and this cell still has major guts.

This is what the welded blank looks like for a Tacmod type, 2 cell stick. As usual - double thickness with 8x0.15mm nickel tab stock, split ends, 8 welds per tab end with the redneck 1 farad cap/SCR spot welder.

I want to upgrade that welder with another capacitor so I can increase the electrode tip size and make a bigger weld. However it does fine and I have never had a weld problem or a tab ever come off a cell. I even accidentally shot through 2 layers of tab at once during this build and it welded them to the cell just fine.

This is what it looks like wired. 14AWG discharge leads and 20AWG balance taps, silicone insulated fine strand.

Above pack shrinkwrapped and terminated.

As usual in end-to-end packs there is an insulating mica board piece under that center tab on the positive side.

This is something new I am trying; W.S. Deans micro connectors as balance taps.

Typically I have used industry standard JST-XH connectors for balance taps and I buy prewired pigtails. I have tried as hard as I could to be standard, but I have had too many problems with JST-XH. In my opinion it is just not durable enough to be used repeatedly and constantly for charging.

It is also difficult to terminate in the field. It is a common type of production connector with separate contacts designed to be crimped to the wire and then inserted into the plastic housing. The pigtails (buying and working with) are a bit of a pain and I don't like the quality of the wire I get with them.

In general I don't like connectors in which the pin is removable. I have had these JSTs spit out pins when plugged in. This is obviously bad, as you could have live metal floating around inside a gun.

2 cell packs have 3 wire tap cables. 3 cell packs have 4. 1S packs don't have or need balance taps. Those are the majority of nerf applications and this type connector covers them. The 4 pin Deans micro is usually red and the 3 pin always black, a convenient color code.

At least for internal charge systems, I will be switching my batteries to this style connector.

Size comparison. The Deans 3 pin is actually smaller and more streamlined than the JST.

The mating connector. These are polarized of course. One pin is offset. I wire the offset pin to the positive end of the pack.

Isn't that neat?

Mega and micro comparison to this pack.

That ought to give an idea of where these can be fit. Primarily these sticks are a stock or buffer tube battery.

With a bunch of other assorted packs. Red cells are Sanyo UR18650SAX, green cells are Sony US18650VTC3, black pack is a 4S Sanyo SAX for a Stampede.

Thursday, July 9, 2015

Tech: The Resistive-Center Rapidstrike Control Circuit

This is an idea for a modification of the live-center RS control scheme, which was inspired by this post. Let's start by taking another look at the diagram showing various possible diode locations in a live-center RS control circuit.

In particular, I'd like to draw your attention to the diode location on the green wire. This was previously identified as an erroneous diode location, as placing a diode here would only slow automatic operation of the pusher and not drop ROF, with the implication that there is no benefit to having a diode in this location.

This is only mostly right: there is a benefit to having a diode here, albeit a small one. This diode would provide a small stability benefit, by turning what would otherwise be a runaway into a single or a small number of trailing shot(s). Planned use of such a system would be a prime example of smart-dumb engineering: smart because it solves a problem, and dumb because a well-made system damn well should not have this problem in the first place. A voltage drop in this location is suitable as a protective measure in a fully stable build which is at risk of becoming unstable. There are several ways that this could happen - degradation of parts resulting in an increased braking resistance was previously noted. The use of batteries with an unexpectedly high voltage is also a possibility. Notably, NiMH batteries may have a higher than expected voltage when hot off of the charger, depending on the charger.

Now: what if we used a resistor?

Using a resistor in place of a diode when dropping ROF is usually not a great idea. A resistor which produces a similar drop in ROF to a given set of diodes will produce a greater increase in lock time, which is undesirable. Furthermore, it is usually pretty easy to tell in advance how much of a voltage drop you want when using diodes: regardless of what motor you have, a voltage drop produced via a diode will have the same effect as if you had used a battery of a lower voltage, whereas with a resistor, the relationship between the ROF and the resistance is more complex and depends on the battery voltage and the motor used.

However, dropping ROF is not what we want to do here, and here, resistors can do something very useful which diodes cannot: they can provide protection in the event of a stalled pusher.

Let's do some back-of-the-envelope calculations to see what sort of resistance we would need here. Let's assume a freshly charged 3S LiPo pack, as this voltage (12.6 V) is the highest that we are likely to see, and an FK3240 on the pusher, because this is a fairly common pusher motor with known specs. An FK3240 draws 1.54 A when operating at maximum efficiency at 3 V, and the effects of a stationary rather than moving commutator on motor burnout are difficult to estimate, so 1.5 A serves as a conservative-ish rough estimate of how much current an FK3240 can comfortably withstand while stalled.

This suggests that the highest resistance which we might want is 8 Ohms. Realistically, we could probably get away with something lower.

What effect will this have on the speed of the automatic operation of the pusher rod? Most of the time, this will not be a concern due to the momentum of a RS's pusher box. The fact that a dead-center RS will terminate a good proportion of the time with the pusher rod nearly fully retracted should give an indication of how significant this momentum is. The worst case would be a marginal trailing shot - i.e. a shot where the pusher is left on the far side of the braking region with little momentum, and the automatic operation of the pusher rod carries the rod through an entire cycle. As the pusher motor experiences a load which is not known and which varies over the stroke, the effect of this resistance is difficult to calculate. However, it is worth noting that 8 Ohms is pretty close to what some people who use resistors to drop ROF use - see this post where Boff of the BirtNerf forums links to some 7.5 Ohm power resistors which he used in a batch of RSs.

So, there you have it: the resistive-center control circuit. Start with a live-center circuit, and put an appropriately-rated resistor on the wire that runs between the battery and the cycle control switch.

Advantages:

In particular, I'd like to draw your attention to the diode location on the green wire. This was previously identified as an erroneous diode location, as placing a diode here would only slow automatic operation of the pusher and not drop ROF, with the implication that there is no benefit to having a diode in this location.

This is only mostly right: there is a benefit to having a diode here, albeit a small one. This diode would provide a small stability benefit, by turning what would otherwise be a runaway into a single or a small number of trailing shot(s). Planned use of such a system would be a prime example of smart-dumb engineering: smart because it solves a problem, and dumb because a well-made system damn well should not have this problem in the first place. A voltage drop in this location is suitable as a protective measure in a fully stable build which is at risk of becoming unstable. There are several ways that this could happen - degradation of parts resulting in an increased braking resistance was previously noted. The use of batteries with an unexpectedly high voltage is also a possibility. Notably, NiMH batteries may have a higher than expected voltage when hot off of the charger, depending on the charger.

Now: what if we used a resistor?

Using a resistor in place of a diode when dropping ROF is usually not a great idea. A resistor which produces a similar drop in ROF to a given set of diodes will produce a greater increase in lock time, which is undesirable. Furthermore, it is usually pretty easy to tell in advance how much of a voltage drop you want when using diodes: regardless of what motor you have, a voltage drop produced via a diode will have the same effect as if you had used a battery of a lower voltage, whereas with a resistor, the relationship between the ROF and the resistance is more complex and depends on the battery voltage and the motor used.

However, dropping ROF is not what we want to do here, and here, resistors can do something very useful which diodes cannot: they can provide protection in the event of a stalled pusher.

Let's do some back-of-the-envelope calculations to see what sort of resistance we would need here. Let's assume a freshly charged 3S LiPo pack, as this voltage (12.6 V) is the highest that we are likely to see, and an FK3240 on the pusher, because this is a fairly common pusher motor with known specs. An FK3240 draws 1.54 A when operating at maximum efficiency at 3 V, and the effects of a stationary rather than moving commutator on motor burnout are difficult to estimate, so 1.5 A serves as a conservative-ish rough estimate of how much current an FK3240 can comfortably withstand while stalled.

This suggests that the highest resistance which we might want is 8 Ohms. Realistically, we could probably get away with something lower.

What effect will this have on the speed of the automatic operation of the pusher rod? Most of the time, this will not be a concern due to the momentum of a RS's pusher box. The fact that a dead-center RS will terminate a good proportion of the time with the pusher rod nearly fully retracted should give an indication of how significant this momentum is. The worst case would be a marginal trailing shot - i.e. a shot where the pusher is left on the far side of the braking region with little momentum, and the automatic operation of the pusher rod carries the rod through an entire cycle. As the pusher motor experiences a load which is not known and which varies over the stroke, the effect of this resistance is difficult to calculate. However, it is worth noting that 8 Ohms is pretty close to what some people who use resistors to drop ROF use - see this post where Boff of the BirtNerf forums links to some 7.5 Ohm power resistors which he used in a batch of RSs.

So, there you have it: the resistive-center control circuit. Start with a live-center circuit, and put an appropriately-rated resistor on the wire that runs between the battery and the cycle control switch.

Advantages:

- Predictable trigger response, as a standard live-center control circuit.

- Reliable pusher position control, as a standard live-center control circuit.

- Protection in the event of a pusher crash and any other sort of pusher jam. This protection is inherent to the circuit, and does not rely on the user to release the trigger quickly.

- Trailing shots are possible, and may be fired with a greater delay than with a standard live-center circuit.

- Safety, though less so than with a standard live-center circuit. An unattended powered blaster which suffers a mechanical failure in the cycle control switch may have its pusher operate continuously. An appropriately rated resistor should reduce the fire hazard, prevent damage to the motor, and prevent battery damage through excessive discharge rate. Battery damage through overdischarge will take considerably longer than with a standard live-center circuit.

Tuesday, July 7, 2015

The Situation With "Meishel" Motors

When I did my electric pistol build, I decided on these 4666kv generic FK130 motors that redditor /u/Meishel found on ebay a while back. However, what arrived in the mail was not in fact the same motor.

It turns out there has been a substitution across multiple sellers, perhaps at the supplier level, of a vaguely similar motor and I was one of the first to receive the new ones. At the time, I was oblivious to the difference, because I hadn't used the original Meishel motor. It wasn't until I put the thing together that I noticed anything remotely amiss (the high speed and noise of these things compared to what I was expecting them to do), and then after redditing my blog post, Meishel commented. Further research blew the can of worms wide open. So here's the deal.

This is a true "Meishel" FK130 motor. Note the SQUARE vent hole in the can, the standard zincplate finish on the can, and the standard length FK-series shaft end which is exactly like the one on the Mabuchi FK180SH-3240 and other Mabuchi FK motors you may have seen.

Proper specs for torque and current draw are maddeningly nonexistent on these, but what we know is "28000rpm @ 6.0V" which gives a kv of 4666.

These motors are well tested with 2S lipo batteries. They turn at ~34500rpm unloaded giving nominal performance, and have response and torque noticeably inferior to the Falcon WFK130SZ-2190, but pretty damn good for a 130 motor, especially for one that uses a simpler and more space efficient 2 cell battery and is thus well suited to pistols where fitting in a 3S pack with enough guts for Falcons would be difficult.

Now this motor is the new one people are getting from former Meishel listings which is NOT a Meishel motor. Note rectangular vent hole, longer shaft (only a good feature for flywheels) and can that appears hot galvanized or plated with heavier zinc.

(right)

This motor is rated at 25000rpm @ 4.8V, giving a kv of 5208. It is wound substantially hotter than a "Meishel".

On 2S lipo, this motor turns at circa 38000 rpm. This is not an optimal setup, speeds over ~35K are not helping with velocity and might decrease accuracy and consistency. Plus the obvious noise. Durability and reliability are not well known for this combo but I don't expect trouble out of these from how mine have acted so far.

Some comments about reliability concerns, brush gear, LiFePO4 batteries, and such for this 5200kv FK130 "banshee" motor in this reddit thread.

It turns out there has been a substitution across multiple sellers, perhaps at the supplier level, of a vaguely similar motor and I was one of the first to receive the new ones. At the time, I was oblivious to the difference, because I hadn't used the original Meishel motor. It wasn't until I put the thing together that I noticed anything remotely amiss (the high speed and noise of these things compared to what I was expecting them to do), and then after redditing my blog post, Meishel commented. Further research blew the can of worms wide open. So here's the deal.

This is a true "Meishel" FK130 motor. Note the SQUARE vent hole in the can, the standard zincplate finish on the can, and the standard length FK-series shaft end which is exactly like the one on the Mabuchi FK180SH-3240 and other Mabuchi FK motors you may have seen.

Proper specs for torque and current draw are maddeningly nonexistent on these, but what we know is "28000rpm @ 6.0V" which gives a kv of 4666.

These motors are well tested with 2S lipo batteries. They turn at ~34500rpm unloaded giving nominal performance, and have response and torque noticeably inferior to the Falcon WFK130SZ-2190, but pretty damn good for a 130 motor, especially for one that uses a simpler and more space efficient 2 cell battery and is thus well suited to pistols where fitting in a 3S pack with enough guts for Falcons would be difficult.

Now this motor is the new one people are getting from former Meishel listings which is NOT a Meishel motor. Note rectangular vent hole, longer shaft (only a good feature for flywheels) and can that appears hot galvanized or plated with heavier zinc.

(right)

This motor is rated at 25000rpm @ 4.8V, giving a kv of 5208. It is wound substantially hotter than a "Meishel".

On 2S lipo, this motor turns at circa 38000 rpm. This is not an optimal setup, speeds over ~35K are not helping with velocity and might decrease accuracy and consistency. Plus the obvious noise. Durability and reliability are not well known for this combo but I don't expect trouble out of these from how mine have acted so far.

Some comments about reliability concerns, brush gear, LiFePO4 batteries, and such for this 5200kv FK130 "banshee" motor in this reddit thread.

Saturday, July 4, 2015

Real funny, Coop.

The thumbnail from Cooper and Unicorn Tactical's new "tactical" parody video. I won't be linking it from here, but check it out, it's worth a watch, it's got rolling around in a pile of darts and everything. But what's with that gun? Let's have a closer look:

I see what you did there.

PS: Countersink your damn screws.

Thursday, July 2, 2015

WASP Completion

This was where I left it:

Now the new bodywork:

And paint. Trivia: Everything red of mine has been sprayed with the same single can. "DZ Customs Red" is ACE Hardware "Rust Stop" (Rustoleum knockoff) "Regal Red" enamel. That can is about 10 years old and has sprayed a bunch of mower parts and other random things too, and now 4 guns! And there is still paint left in it!

One of the great things about the Rustoleum industrial finish, it covers forever and beyond. Super cheap and handy. I spray the white stripes over the red in one coat, too. Perfect coverage, though I could get smoother paintjobs if I would be more careful and patient and buy some fresh paint.

That was a while back. The battery and motors arrived recently and I put this thing together.

Generic FK130SH

Installed in a Stryfe cage.

The battery I am using, a Zippy Compact 2S 850mAh 25C.

The only battery box mod, aside from gutting out all the AA related stuff from the inside, is to grind this spot. This is where the wires exit the wrapping of the pack and the relief avoids pinching them.

Dropped in place.

Installed. There is a PVC piece added to prevent the pack from moving forward, and I have replaced the JST RCY with a Deans Ultra.

Everything crams in nicely. The battery box cover has had the ribs removed on the backside

Closed.

Internals. Wired with 16AWG teflon, full size micro, all standard stuff. You can also see the "vortex" muzzle device here

This feed guide is one of the defining features that separates this from "just a Stryfe". It is ~2mm sheet, and bonded to the underside of the old support area for the lockbolt/dart sensor that of course went in the trash.

And this is what it does; support the top round in the mag and prevent it from working upward through the feed lips over time. This is going to be a sidearm, so this is a very necessary feature for reliability. It prevents malfunction clearance without dropping the mag and prevents toploading, but it allows trouble-free use of mags with very strong springs (like 6-rounders, which are what will be used in a pistol) over any period of time.

You can also see the spring feed guides installed in the cage. These are there to provide spring pressure to hold darts in the mag and avoid any remote chance of the dart working forward into the flywheels and locking them up.

With my primary.

Now I just have to wait for that holster to arrive.

I am happy with the results of this build (which are alright response and nominal velocities), but I don't like how loud and rough it is. It could use a set of better balanced flywheels (but definitely can't handle any more flywheel mass). These motors rev a bit too high in my opinion, and the battery is also too small and has too high an IR to get either optimal motor performance or optimal service life out of the battery. I still don't like flatpak lipo and I still don't like 130 motors.

However, in terms of a cheap power system ($5.10 battery, $3.58 motor set) that is available at present and fits into a pistol form factor, it is pretty damn good. It has a mean buzz and a nasty sting and it will sure get me out of more bad situations than a single-action revolver.

Subscribe to:

Comments (Atom)