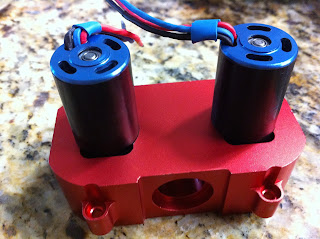

This is a Gen 2 Artifact Red milled for 20mm round cans and fitted with GWS GWBLM005 motors (20x42mm, 4600kv, Rm=0.1).

I initially installed my pair of rifled full profile Artifact flywheels for testing, knowing full well that trouble could lie ahead.

Well, one of them had a weak shaft fit and walked like hell; but that seems to have been a quality issue, not a design one. I currently have Hooligan flywheels on this setup, which have done very well.

Shaft fit definitely becomes an issue here. These motors have similar capabilities to brushed 380 motors, though peak torque of this type of motor system is a far more complex matter.

And you thought 180 motors were long?

There is a physics rationale for the use of long, thin, low-slung motor designs as flywheel drives: for a given torque capability, they minimize rotor moment of inertia. Favorable kv for the single-stage SSS application being available, and suitability for cages with this flywheel diameter, are other considerations in why I select the 20x40mm class of motors.

Same can diameter as the 20.4 flat can brushy. And yes, same 2.0mm shaft diameter. Takes standard SSS flywheels without modification.

And another comparison. Cage on left with smoothies and 3240s is from the original 148fps/Gen3 koosh session.

Cage modification is simple clearance. (Thanks to Ferrera Tooling in Lakeland for machine work)

These particular motors have the 20.4 flat can mounting pattern in the endbell in addition to two holes of the 20mm brushless pattern (standard?). They bolt up to the stock Red mounting holes. Note that the more available Turnigy XK2040 does NOT share this feature and the cage will need its hole pattern added to use it in such a conversion. If I do any more of this bit of custom work, which I probably will, I will be using the Turnigy motors with that change.

Note DRS Performance is now shipping their latest generation of cages with round mount sockets, and 20mm motors should drop in (and bolt up, if you use GWS). Overall, I do not know why anyone, including DRS or Artifact, ever designed a cage with non-round mount sockets in the first place. It is harder to draw and machine a double-D shaped socket for flat can motors than it is to just punch a 21mm hole and it doesn't provide any advantage whatsoever when the motor is already bolted down by the face surface and doesn't even touch the walls of the socket.

Test setup: Controllers are ZTW Spider 40A and are running stock SimonK. The other bit of electronics connected to the switch is the Throttle Interface Module (TIM) which contains an ATtiny85 development board and is responsible for turning switch inputs and a preset trimpot into a PWM throttle signal.

This power system is designed around 2S lipo or equivalent, both because available motor kvs were ideal for it, and because the intended application has perfect space for a 2S Monolith stick.

Don't worry though, not everything went smoothly. Bugs manifested. I solved them, however. It's good to go now. More on that in the next post, but for now, the cage in final state, terminated with 3.5mm bullet connectors and fitted with a set of Hooligan Blaster Company's excellent SSS flywheel product.

Something about that cage all finished up properly with the bullets on the phases is extremely satisfying.

And a controller install mockup into what very well may be my last series of stock-based builds, the T17 concept. Yes that is a Stryfe receiver.

In a nutshell, I have had it with RS receivers. My 2015 T3.1 in the state it is in now has been a sterling and trustworthy right arm if a bit mechanically dated, but the design of the host gun is a trouble source where the Stryfe is not and that is the damned matter of cage/inner barrel alignment. So while I am still even using host guns (which as of my last near-complete project, Prometheus, I have already began phasing out) I am going to use the soundest platforms and do the least fiddling and dialing-in.

Secondarily I am migrating to shorter carbines. Inner barrels set up right aren't that bad on velocity and consistency thereof but they do have a cost and a risk of interaction with darts, especially the koosh.

What's left hanging is a question of bolt drive. I don't want mechanical semi-auto. I also like the compact packaging and tactile-feedback characteristics of sector gear drivetrains over the Scotch yoke type (RS) though the latter are, obviously, impact-free, spring-free and shoot more smoothly. So, ...I haven't really dealt with testing and reviewing those Stryfe conversion kits, but I bought an XSW kit a while back. This comes with a very solid Delrin bolt (with the rack integrated) and a very solid Delrin sector. Both are crude, flashy, warpy molded parts but they ARE robust as all hell, I will give them that. What worries me is the "TT" 48:1 gearbox it is designed around, which is tiny inside - but seems to be doing great around the NIC.

I bought some 63:1 metal boxes from Pololu with some other parts, planning to mount one of these to drive an XSW sector gear - but on opening one for a motor swap to a useful kv motor, holy shit it's tiny inside too and I would have to do much fab and lose much trimness from the protruding motor. Most available gearboxes/gearmotors are either unfavorable form factor, or also a durability concern, and whoever designed the XSW kit was right - the TT box, also featured in the VLocity paintball loader and many little robots, fits this space like magic. So, as much as I am scared of the TT box, I am going to give it a shot first and beat the crap out of it on testing and local events with a backup gun handy. Seemingly fragile and doomed things sometimes just work. If not, I have better ideas.

Here's more of the device, tentatively called T17 Super Duty.

Sadly I am already looking to the future and beyond this, but screw it, tomorrow we're going full auto.

Oh, nice to see this getting posted!

ReplyDelete