Problem one is that I have been having incidences of a specific and aggravating malfunction with this cage, which has been occurring solely with used waffle darts (never anything else, especially not accustrikes). The failure mechanism is the foam being dragged around with the lag side of one of the flywheels after the contact zone and getting sucked into the little gap where the bore re-forms, created by the extremely concave wheel and the cylindrical flywheel cavity in the older Hy-Con cages. The thing then seizes up tight as a rock. Sometimes the dart can be unwound out the breech or muzzle by hand. Other times a rod is required. Not a good situation.

I was aware of this misfeature, as well as potential solutions to it, and it was my greatest uncertainty when I designed the original Hy-Con system. The reason for its persistence is or perhaps was that machined cages are or perhaps were planned down the road, and any internal geometry gnarlier than a cylindrical flywheel cavity would probably result in a significant cost increase and prevent a one-piece cage from being possible to assemble.

Unfortunately, this does not appear to be working out.

This blaster must shoot any common super/ultrastock ammunition, and it must be able to shoot garbage. It's allowed to chop or mutilate garbage in any way, and it is also allowed to have garbage accuracy and consistency with garbage as is the reality of garbage, but it is never allowed to stop firing and require attention to clear, even if the ammo is garbage.

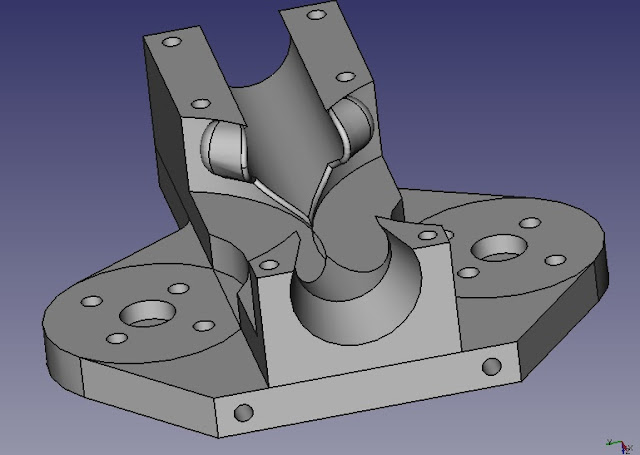

And so the CADding begins again. I am holding off on further work on the Production T19's "Gamma" cage for the moment until I get the internal geometry of the Hy-Con cages nailed down and field tested. To that end, this is what I am calling "Beta Prime", a straightforward addition of the experimental feature to the old Model Pandora cage.

Note those protrusions - they stick down into the flywheel grooves, and fill that stupid little offending gap in so stuff hopefully can't get pinched in there and cause a mess. They have about 0.75mm clearance off the rims of a 9.5 wheel, so there is a bit of room left for the 9.0.

This is actually a feature the PFDL cage has had for a while now. It probably is overkill with the low envelopment there, nor does it seem to be necessary with high-envelopment smaller diameter systems like Eclipse, Ultracage and DrSnikkas cages that generally just have a cylindrical cavity and ignore that gap, but I may have discovered a case (high envelopment AND one of the largest diameter systems ever in practical use) where it is very, very necessary to have that little groove filler doohickey.

I should also mention my suspicion that this troubling malfunction is all the fault of waffle darts all along once they get used and the tips start getting loose - the root cause may be the waffle tip grabbing/sticking in the 14mm barrel and causing the foam to buckle or bunch-up behind at which point the lag sides of the wheels are going to nip the foam. I had the same exact jam happen when I was using TBNC David's FDL for one round and put a couple hundred rounds through it. The difference is that when T19 does this, the dart becomes a mangled, compacted, FUBARed shitshow. When the FDL did it, the dart was still pinched and the motors still locked up, but grabbing the dart and ripping it out, then dryfiring dislodged all the debris and restored functionality. That I am guessing is the limit to the value of the gap-filler doohickeys and the true solution is to not shoot those darts and use something else. I am having massive second thoughts on Accustrikes/clones - they are AWESOME in CQB and HvZ.

Anyway, here's the result when you add wheels:

Note the protrusion is asymmetrical. The motor mount side cuts it a bit closer to the wheel profile with a 45 degree edge there in the hopes of printing more easily.

You can also clearly see another related change - the cage no longer splits straight down the bore axis. The parting line was moved 4mm from the motor mount part toward the cover part. That gap filler protrusion makes assembly impossible if it is not entirely in the motor mount section of the cage. Note it also makes assembly impossible if the guards or anything else are integrated into the motor mount section without sufficient clearance and block the sides of the motor mount. You must be able to mount the wheel to the motor, slide the motor in from the side, and bolt it down to get the wheel rim past the protrusion.

There are also some minor external changes on the Beta Prime cage from the previous Beta. Guards were thinned by about half but are still quite robust, and some edges have fillets. No big deal.

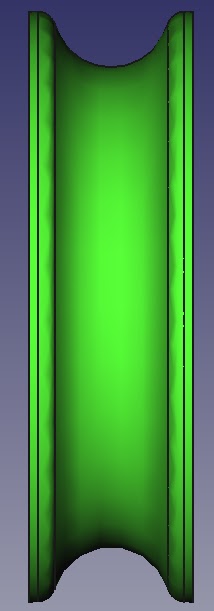

I have also modelled a new series of wheels. Changes include more refined rim backside geometry, 0.5mm larger OD to take better advantage of the standard Hy-Con cage clearances and take the rim-to-rim clearance down to a nominal 0.5mm, a series of gap settings that presently range from 11mm to 9mm, and radiused rims rather than chamfered rims, which are a bit smoother and sacrifice less contact at the edges.

This one is a 10mm, incidentally. I have high hopes for 10mm with this system being quite competitive on velocity but easier on darts than the 9.5.

This cage has Gen 1 wheels. Note what happens with those rim chamfers. Also note what is considered a large rim clearance in this day and age, not a fitting thing for the original "100%" envelopment cage.

This one has Gen 2 - note softer edge provided by the fillet instead of the hard chamfer, and note the closer rims and generally much better fidelity of the hydrostatic compression profiles to the ideal circle.

Finally, since I didn't get any images of the real blaster that show the drivetrain guts of a T19, have a Model Pandora cross-section. Perhaps that will clear up some things.

Specifically, look right above the NEMA 17 mounting pattern and you can see the cavity where the crank web sits, and above that, the bolt guide rails. The bolt is completely 2-D like a sheet part (the proto one IS a PVC sheet part like the crank web), and is about 6mm thick. The limit switch bolts to the little perch behind there. The purple top cover forms the upper rails, capturing the bolt in there, and the rest is just a magwell, a closed breech guide and a cage and that's all there is to it.

The stepper motor's shaft is shortened considerably, before anyone asks.

More updates once I get my Prusa going. That's gonna be fun...

Awesome post.

ReplyDeleteNow these posts are why I check this blog multiple times a week.

ReplyDeleteNice idea with the special lip to keep stuff from messing with the flywheels. Is that design only for the one side, or could you add the lip to both flywheel sides for a total of 4 lips instead of 2. Or is that unnecessary?

ReplyDeleteAlso, why were you gone for several months?

There's no reason not to have groove fillers on the other side of the wheels too, but there is also no reason TO have them there either. The direction of motion of the flywheel surface there prevents anything from getting wedged into that gap.

DeleteI wasn't gone. I just didn't post for a while.

Very cool. I've been loving the original prototype hy-con cage I've been using, but I have ran into the jamming issue you mention.

ReplyDeleteDoesn't happen often enough to be a deal breaker, but it'll be nice to have that fixed.

Any idea when you plan to release the refined files?

I will post them right now, since I just tested the mod at last game and it has cured the problem. Keep in mind a couple things: The cage with the mod is not a "Protocage", it is a Beta for my T19 prototype. Do you need a Protocage with the modification for your blaster? Also, I am in the process of reworking Beta into an improved design that is more rigid and if you use any of the original designs make sure you print them as solid as you can.

DeleteFiles are up at https://drive.google.com/drive/folders/1pEK2AXus15fKDxj3zVOYPo-EVS80P-RH?usp=sharing while I get the confusing github repository stuff squared away.

DeleteThe cage with the groove fillers is Hy-Con-BetaPrime. Also, the latest wheel models are up including one I haven't yet discussed on this blog but was running in the last few videos at TBNC.

Thanks!

DeleteI'm using the hy-con prototype cage, I'll take a look at the designs and see if I can make the Beta work.

The mount I'm using in my swarmfire integration is pretty flexible, it's just a plank of wood with the 8 mounting screws for the motors going through it, BetaPrime might be a viable fit.

I've been printing at 90/100% infill so far, and the cage has held up without trouble, hopefully that won't change.

I'll give BetaPrime a shot over the week, if I have trouble fitting it, then I'd appreciate a prototype-prime cage, but no obligations, you are providing this all for free with a this is a prototype warning after all.

If you run into trouble it won't be too hard to add the groove fillers to a protocage model. Only issues I see you running into with Betas is that the motor mount pattern is clocked 45* (to point the phase wires backward) and you may have to remove the guards from the cover half to fit your blaster. Motor mount thickness is the same so alignment will work if you redrill those holes.

DeleteIf you printed with high infill you are good to use the Beta and Protocage as far as I can tell at this point and won't be losing much if any velocity which is the consequence here. Never had anything Hy-Con related fail/bust.

I went ahead and deleted the guards and rotated the holes in tinkercad, as far as I can tell it'll fit, I'll know for sure soon.

DeleteThanks again for a great design.

And done, the prime cage and gen3 wheels are happily working in my blaster.

DeleteFired 10 mags through with 0 issues.

Wound up with two waffles darts looking like this, https://i.imgur.com/z8oHTGN.jpg, I imagine these are the ones that otherwise would have caused a jam.

Thanks!

could you elaborate more on the waffle/accuclone choice? After your mention that waffles perform better at high velocity and long range than accustrikes, I tried to do some testing myself, but I hardly saw any difference at 160 fps. I'm planning on bulking a massive amount of darts, but then I'd really like to make a well informed decision between the two darts, maybe you could share your thoughts more in-depth? Love the blog, and that blaster is absolutely amazing.

ReplyDeleteYou probably won't see the benefit with waffle unless you regularly take long range shots. If you are personally finding Accustrike to not have any issue with velocity retention then it is probably a marginally better choice. In my experience Accustrike is more consistently stable and precise, even from equipment that won't shoot waffles accurately.

DeleteThe T19 used to have some problems with wild shots with waffle in addition to jams and thus accustrike was helping it out considerably, but the groove filler modification fixed both and now it is a lot closer match between the two.