That is electrical wiring.

Now, in this modern era we have many electric guns; whose primary energy source for basic operation is electricity.

Now, in this modern era we have many electric guns; whose primary energy source for basic operation is electricity.Like RC models or airsoft guns, many aspects of the performance of such a device are dependent on the characteristics of its electrical system. Yet, I continue to see the electrical system poorly understood and corners cut.

>> Why You Want Better Wiring

First, let's talk about current, voltage, and resistance.

Electric current flowing through wires is analogous to water flowing through pipes. Voltage is "electrical pressure". Current, the rate at which charge (electrons) flows, is like the flow rate in a pipe.

Like all pipes and ducts, all elements through which electric currents can flow have a finite "capacity" to carry current - a certain amount of "friction" per unit of flow passing through them.

Resistance is the electrical equivalent of friction loss in a pipe.

If you have ever worked on or experimented with pipes or hoses and fluids flowing through them, you will understand what happens when you use a pipe too small for a given flow rate - there is a large loss of pressure through the pipe. Sizing wires is just like sizing pipes - you need to use a wire (or pipe) large enough that the current (or flow rate) does not cause an undesirable amount of voltage (pressure) loss and wasted energy.

Perhaps Ohm's law, V = IR, makes more sense now. If you have a circuit element with current flowing through it, a voltage will be present across that element that is proportional to the current I and the resistance R of the element. That voltage represents a decrease from input to output - like water flowing through a pipe drops in pressure due to friction. Also note that when a current passes through an element and voltage drops, energy is being lost. That energy becomes heat.

In short: You need to use a wire large enough to handle the current you want to pass through it without causing an undesirably large drop in voltage.

>> So what does undersized wiring do to a nerf gun?

In a nutshell, it universally harms performance.

Poor wiring, along with other sources of parasitic resistance, result in a loss of voltage delivered under load.

In qualitative terms: Undersized wiring will make your motors more sluggish. It will harm their ability to produce torque.

AEGs (electric springers, such as Stampedes, Swarmfires and Vulcans) will have poorer trigger response and lower cyclic rates of fire.

Flywheels will accelerate more slowly, lose more speed per shot and take longer to recover.

All of these things are bad, m'kay?

>> So what size wire do I need?

That depends entirely on the application.

How much current are you going to pump through it?

There are guides and charts available for sizing wire in the RC hobbies - but really, if you are Doing It Right, sizing wire is intuitive. Furthermore, all of the most common applications in the world of nerf can be handled well enough by just using the same versatile size of wire - 16 gauge. It's good for a few dozen amps in these short runs, and is often used in airsoft rewires as well.

If you happen to be running more current through something - say, 20-30 amps continuous - step up a gauge or two. 12 gauge is good for 60 amps or so in RC use, which (like other RC practices) means it's definitely good enough for nerf. If in doubt, look to the RC hobbyists' wisdom - they have a serious concern for high-performance electrical and will not be found to cut corners!

Just to help out less electrically oriented nerfers, two very common applications are the stock 130 motor flywheel guns and the 360 motor electric springers. These are the stock setups - the most common. 360 motors should ideally be wired with 16g. The flywheels are less demanding - they usually draw 15 amps or less in a stall or startup condition. However, and I will get to this later, I don't bother with buying any smaller wire, and I suggest you do the same.

>> Wire Types

When you go shopping for wire, you will run across a bewildering variety. Teflon insulated, PVC insulated, building wire, solid wire, hookup wire, primary wire, silicone insulated, hobby wire...

Firstly, there are 2 classes of insulated copper electrical wire: solid and stranded. You want stranded, never solid. Solid wire is used for stationary applications, like mains wiring in buildings. It has absolutely no place in a gun where it has to be snaked through tight spaces, flexed and subjected to vibration. It will fail, or fail something else, in short order. I feel like I really shouldn't have to say this... It should be common sense not to use solid wire... but I have seen people put solid wire in a gun and I have been the one to repair it when it dies. So, newbies: Solid is BAD. Stay away from it.

Stranded wire's variety comes mostly from two properties: strand size, and insulation.

The coarsest stranded wire is stranded building wire. This stuff is for the same purpose as the solid variety. Once again, this SHOULD be common sense that YOU DO NOT WIRE A GUN WITH THIS. It's not flexible enough and will fatigue and fail. I say this because I know many nerfers are Home Depot junkies and if I DON'T mention this stuff, someone will think it's OK to use. IT'S NOT. Those spools of THHN insulated stranded wire on the big rack at Home Depot ARE NOT FOR WIRING GUNS WITH. Got it?

Next in strand fineness is hookup wire - also called primary wire, appliance wire and various other names.

It is usually PVC insulated. Being that it is substantially more flexible and fatigue-resistant than building wire, it's perfectly fine to use. You can ram it into the convoluted spaces available in a gun and count on it not to internally break unless you really abuse it.

Moving on down the strand size ladder, we have hobby wire.

This stuff has VERY fine strands and is highly flexible and extremely resistant to fatigue. It is usually silicone insulated. Silicone insulation is abrasion-resistant, heat resistant, does not degrade over long periods like PVC does (by losing plasticizer and becoming brittle) and is very flexible. Silicone hobby wire is just SWEET stuff to work with. If you need maximum flexibility or will be bending a wire a lot (such as the leads for a battery pack, or an external connector pigtail) this stuff is the ticket. It's expensive, though.

I usually use 16 gauge, PVC insulated stranded hookup wire for almost everything. It has the right balance of low cost, small diameter and flexibility with current capacity.

I wouldn't even bother with anything smaller than 16g. It's a hassle to have more wire to buy and keep track of, and smaller wirea are also mechanically weaker. I only use smaller wire when I have to fit into a small area and the 16g is causing problems or is too difficult to work with.

>> Stock Wiring?

So what about what comes in the gun?

In short: It almost always sucks. You should upgrade it.

For Nerf's electric springers, the stock harness is usually something like 20 or 22 gauge, which is marginal. Not terrible, but not mega awesome either. Don't feel bad about using it, because performance gains will be minimal from changing it - but it's not the best. Upgraded motors, however, demand bigger wire.

Flywheels are where most of the trouble is.

The stock wire in most everything, including what Nerf puts out, is HAIR thin. Even for stock 130 motors, it's quite mediocre. For motor swaps? Forget about it, you NEED to rewire! The stock crap will look like a big resistor once you get up to more than a few amps! Hell, it already looks like a big resistor at a few amps...

Rewire your flywheel gun. It's always a winning move.

And remember, when rewiring, you can't fix one problem and ignore the other 10 nearby sources of parasitic resistance.

>> When In Doubt, Dike It Out

Wiring is not just about using the right wire to carry currents - it is about properly constructing the whole SYSTEM. What we want here is to have the cleanest, most unobstructed current path possible from the batteries to the motor(s). A stock harness is not designed according to that goal. It generally has a bunch of unnecessary components in it and is excessively long.

The title of the section is a good guideline.

| |

| Yeah, they have seen better days, haven't they? |

If there is a switch, a piece of wire or some other component that is not contributing functionality that YOU need or want, you should get rid of it! Switches and wire have resistance. Resistance is bad, as we already established.

So when faced with whether to take the magwell switches out of your Rayven or not, ask yourself: "Does this switch here do anything useful?" The answer is most likely "No!" Don't you even think about taping a switch down and putting it back in place instead of removing it! Grab your dikes. Cut it OUT of the harness and be done with it!

There are other components you should be aware of:

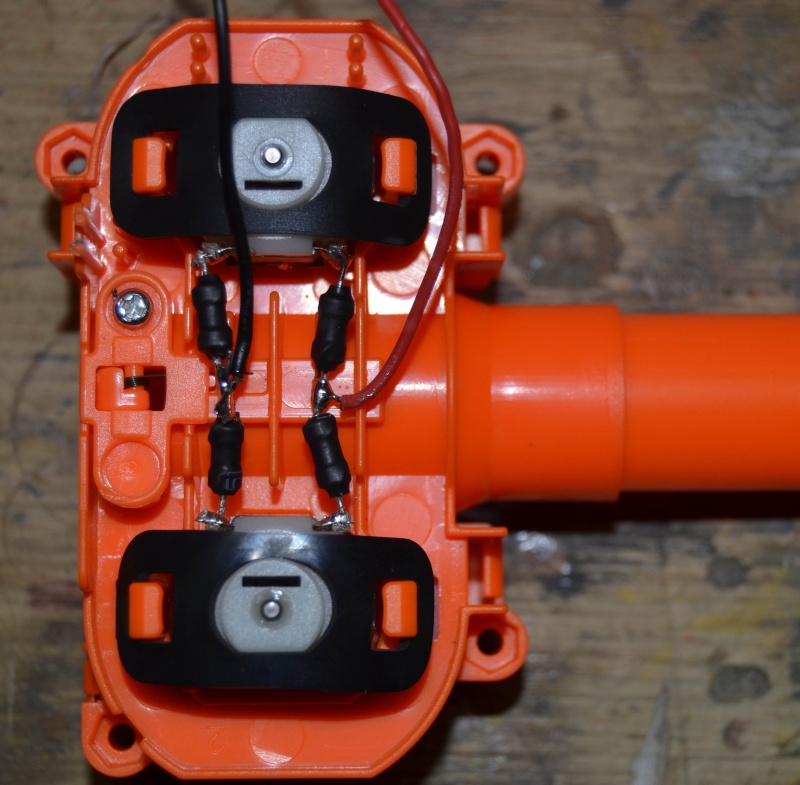

Chokes

These are inductors. They are placed in the stock wiring harness along with capacitors to suppress RF noise from the motor. Since most Nerf guns do not have, or need to operate in immediate proximity to, sensitive electronics or radio equipment, these are unnecessary. Remove them.

|

| Stryfe stock wiring with inductors |

Positive temperature coefficient (PTC) thermistors

These are a type of resistor whose resistance has a strong positive correlation to temperature. The higher the temperature, the higher the resistance.

The PTCs present in a stock nerf gun's harness are used for overcurrent protection. They are of a type that acts like a resettable fuse - if more than the PTC's rated current flows through it, the small resistance it has at room temperature generates enough heat to raise the temperature of the device to a point where the resistance sharply rises to a very high value. This throttles the current to near zero in an abrupt, switch-like manner. Once the PTC cools, its resistance returns to a very low value and the circuit operates normally.

There is a major problem with these in our MODIFIED nerf guns, and that is that the rated current is very small compared to the normal operating currents of a mod gun. You may have experienced this when you hooked up higher voltage batteries (resulting in more current being driven through the motor(s)) to i.e. a flywheel gun, and observed that it won't run, or "overheats" and dies after a short period of use.

A common myth is that there is "overvoltage protection" in stock guns - there is not, only a PTC "polyfuse".

My stance on the devices is that they should be deleted - no exceptions.

They are NOT correctly sized for mod guns.

They can cut out under normal conditions, with potentially serious consequences for HVZ players and others who desire reliability from their gun.

They can also fail by breakdown at high voltages, resulting in a bang, a flash and magic smoke. The Vulcan's stock PTC is prone to doing this.

If you want overcurrent/short circuit protection for your mod, install a CORRECTLY SIZED fuse or PTC. The stock one is not what you want.

Diodes

Only the original green M69 Rayven currently has one of these from the factory - on a small PCB in the crossbar of the thumbhole stock. Its purpose is to prevent reversed battery polarity from causing reverse flywheel rotation, which is kinda pointless.

Remove this. Diodes have a forward voltage drop. BAD!

Printed circuit boards (PCBs)

|

| Vulcan motor PCB |

These are used in Nerf's products as a wiring and assembly aid. The Swarmfire and Vulcan have PCBs connecting the motor terminals to the harness, as well as acting as a substrate to mount chokes, motor suppression capacitors, and the Vulcan's PTC.

The problem here, in addition to the useless junk on the PCBs, is that your current path is going through the little copper foil traces of the PCB. Those are not the low-resistance paths we want. Get rid of them! Desolder the PCB and solder your wire straight to the motor terminals.

The Stampede and all stock Nerf flywheel guns have small PCBs on the motors as well, but the current path does not pass through them - they are simply soldered to the motor terminals in order to easily connect suppression capacitors. These can be ignored.

Many stock switches also have a small PCB on them with current going through traces. These are, once again, used for convenience rather than for any reason related to electronics that would typically be found on a circuit board. If you are really OCD about it, you can solder the wire straight to the switch terminals leaving the PCB in place - OR you can replace the switch, which is the correct course of action anyway!

Capacitors

These are another means of keeping electrical noise down.

Once again, it should be common sense, but direct current CANNOT FLOW THROUGH A CAPACITOR. You will never find them in the current path - only ACROSS parts of the current path.

Generally, there is no reason to either remove these nor to keep them. Do what you will with them.

Terminations and connections

Twisted together wire splices with no solder? Poor soldering? Spring terminals? Crappy battery connectors (i.e. Tamiyas)? Yeah, those are all BAD.

You want to make your wiring harness as SHORT and DIRECT as possible for maximum performance, durability and reliability.

There is a specific case I always see that just grates on me, and that is how batteries are wired up for Stampedes.

The stock configuration has a 6 D cell holder attached to the buttplate of the gun. This slides into the battery box and makes contact with some spring contacts mounted in the receiver right above the pistol grip.

That would be fine... IF IT WAS A FLASHLIGHT.

But it's not a flashlight, is it? It's something with a 300 series motor in it that we want to perform to its best.

If you are not using alkaline D cells to power your Stampede (and honestly, that is a horrid battery setup) there is no reason to use that battery sled or those spring terminals. Rip that crap OUT! The terminals, the sled... everything (and kill the nearby PTC while you are at it). Wire your new battery connector or cell holder directly into the harness and bring it right out into the battery box with enough wire length so you can install your batteries when the gun is assembled.

All better!

>> Soldering

In short: It's necessary.

I am going to post about soldering later, but for now, I will just note that I consider a soldering iron a mandatory tool for the modern electric nerfer.

You cannot get by with twisted wires, wire nuts or any such ways to totally fumble a wire splice. You may as well just leave it stock if you are going to do that. Not only is there a large parasitic resistance associated with that, but twisted wires are very unreliable.

Solder everything. Ideally, every connection (aside from proper low resistance power connectors rated for the current they will handle) should be soldered - the exception is, of course, if you are in that minority of people who uses a crimp type termination (Anderson Powerpoles anyone?).

>> Heat Shrink Tubing

You also need some of this stuff to insulate wire splices and terminations. Electrical tape is fine for working on building wire, but in nerf? Forget about it! Tape comes off easily, is difficult to wrap tightly, is messy, leaves adhesive residue everywhere and is just kinda ghetto. Once you use HST on wiring you will never tape again! I consider it a critical material for electrical work of any sort.

It's oriented polyolefin tubing that is formed and stretched during manufacture. When heated, it recovers its original diameter, tightly fitting to whatever is inside. Using HST on wire splices and such is simple: cut a piece of tube longer than the joint or splice you are going to cover up, always remember to put the tube on the wire BEFORE soldering, solder (keep the tubing away or it will shrink prematurely!) and then slide it over the joint and heat it.

You can shrink HST with a heat gun or a lighter, etc.

3/16" is a good size for nerf.

>> Power Connectors

If you need part of your wiring harness to unplug, you need a connector. If you are using a battery pack, you also need connectors to plug that in.

All that matters here is that you use something durable, reliable and rated for the current. Generally, anything favored in the RC hobbies (Deans, XT60, bullet connectors, Powerpoles...) is suitable. Don't use Tamiya connectors; they are unreliable.

I am a loyal user of the W.S. Deans Ultra Plug, famous in RC and common in airsoft, but connectors are a very personal thing. If you get on the grid and start Googling them, you will find flame wars about battery connectors. It's that bad. I do not have some sort of agenda regarding what connectors people use (well, outside of my effort to convert every pack-equipped electric gun at UF to deans) and I am not blind to the fact that there are tons of options other than Deans.

I am a loyal user of the W.S. Deans Ultra Plug, famous in RC and common in airsoft, but connectors are a very personal thing. If you get on the grid and start Googling them, you will find flame wars about battery connectors. It's that bad. I do not have some sort of agenda regarding what connectors people use (well, outside of my effort to convert every pack-equipped electric gun at UF to deans) and I am not blind to the fact that there are tons of options other than Deans.The only caution regarding deans is that there are a LOT of knockoffs. Avoid them! They are garbage. If you use Deans, use only real ones, which are always sealed in a bag with a giant Deans logo on it.

So remember, big wire, short and direct, and no unnecessary junk, and you will be ahead of 90% of the other guys who don't know how to approach electrical work in nerf.

Stay vigilant people...

What sort of replacement switches do you recommend? I'd really like to have a switch that fits where the stock flywheel acceleration trigger is. But don't know if that's possible for switches rated to ~10A which is what I'd like to have for a solar SM2 swap.

ReplyDeleteUnfortunately I don't believe any switch of that form factor and capable of handling high currents is available - at least not easily.

DeleteI would just bite the bullet and upgrade to a microswitch. Some cutting is necessary, but some epoxy putty is all you need to mount it and the button feel will be far superior as well.

On the subject of heat shrink tubing: I've found that hotglue is a viable alternative. Unlike electrical tape, it won't work loose and come off. It also has the advantage as doubling as an adhesive - it both electrically insulates and holds things in place at the same time. On the other hand, it is ugly, takes up more space, takes effort to remove when you want to further modify your blaster, and goes everywhere in horrible sticky strands if not applied carefully. I wouldn't recommend it over HST - but it served me well in my first major project and might be good enough for the job at hand.

ReplyDeleteThis is something that really needed to be said for the majority of Nerfers, well done in the explanation. Couldn't have put it any better myself, or at least not as clearly.

ReplyDeleteI would just like to know, what size is the flywheel motor for a nitron ? its larger than the others, anyone have some answers?

ReplyDeleteTY! I can now finally understand nerf electronics and circuitry! Your a life saver!

ReplyDeleteThank you for this. I've been looking for exactly this sort of post for a while now as I look to get into modding. Bookmarked for sure.

ReplyDeleteBookmarked. Thank you for this, it's exactly the sort of thing I've been looking for to get into modding.

ReplyDeletepurchase link to the wire you use?

ReplyDeleteI use a variety of wire, what are you looking for specifically?

Deletegreat article

ReplyDeletewould you recommend an E-Flite LiPo Battery 11.1V for a battery swap, if not then what else?

ReplyDeleteWhat sort of battery would you recommend for a rewired Stampede with a 9kg spring? Specifically with zippy lipos or lifepo4, how many cells/voltage would you run with?

ReplyDelete3S LiPo, or 4S LiFePO4 is standard for 60t 360-equipped Stampede.

DeleteIf you really want to mess with the bleeding edge of reliable ROF on these clunky old things, 4S lipo. This will take considerable tuning to not run away.

Nice Electrical Guide! This helped me rewire my crappy stock nitron to a painted, minimized 10 dps nitron. (4S LiPo)

ReplyDeleteNice Nerf Electrical Guide! This helped me remove unnecessary crap out of my nitron and elite rayven. Now they run on Turnigy 4S LiPos with full rewire and motor swaps.

ReplyDelete